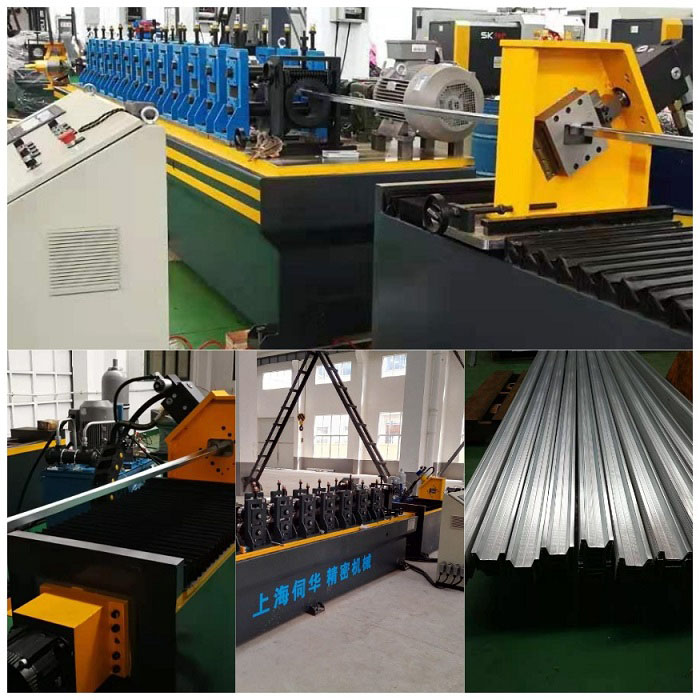

Izithuthi B iprofayili yemoto ye-chassis yokuqinisa umgca wokuvelisa umqadi

I-uncoiler ezintathu-in-one ezizenzekelayo ngokupheleleyo kwindawo yokuqala isebenzisa ulawulo loxinzelelo lwe-servo ukuqinisekisa ukutya okuzinzileyo, ngelixa i-16-roller echanekileyo yokulinganisa isusa uxinzelelo lwezinto eziphathekayo. Ngaphezu koko, inkqubo yokulinganisa i-laser iqinisekisa ukuba i-sheet flatness ukuya kukunyamezela kwe-≤0.1mm, ibeka isiseko sokwenza okulandelayo.

Ixhotyiswe nge-punch enkulu ye-600-toni kunye nokuchaneka kwe-punching kufa, ifezekisa ukuchaneka okuphezulu kwe-± 0.1mm kwimingxuma yokufakela i-anti-collision beam, ukuphelisa imfuno yokulungiswa kwesibini.

I-Precision punching die ibhekiselele kwisixhobo sokuchaneka okuphezulu esisetyenziswa kwiinkqubo zokungqinisisa ngetsimbi ukugqobhoza, okungenanto, okanye ukugqobhoza izinto ezinokunyamezelana okuqinileyo kunye nokugqitywa komphezulu ocolekileyo.

Ezona mpawu:

1.Ukuchaneka okuphezulu - Ukugcina ukunyamezela okuqinileyo (kaninzi ngaphakathi kwe-± 0.01mm okanye ngaphezulu).

2.Umgangatho oFine Edge - Uvelisa ukusika okucocekileyo kunye ne-burrs encinci.

I-3.Ukuqina - Yenziwe kwintsimbi yensimbi eqinile (umzekelo, i-SKD11, i-DC53) okanye i-carbide ubomi obude benkonzo.

4.IiMilo eziNgxaki – Ziyakwazi ukugqobhoza iijiyometri ezintsonkothileyo ezinokuphinda-phinda okuphezulu.

I-5.I-Optimized Clearance - I-punch-die clearance eyiyo iqinisekisa ukuhlukana kwezinto eziphathekayo.

Inkqubo ye-50-pass progressive rolling, ephuculwe yi-software ye-German Copra, iqinisekisa ukuguqulwa okufanayo kwentsimbi ngexesha lokugoba okubandayo. Inkqubo yokuhlola uxinzelelo lwexesha langempela, esebenza ngokubambisana ne-servo drive, igcina ukunyamezela kwe-dimensional ± 0.3mm kwicandelo le-B. Utshintsho lwe-arc oluchanekileyo kwii-angles ezichanekileyo zithintela uxinzelelo loxinzelelo.

Izinto zerola: CR12MOV (skd11/D2) ivacuum unyango lobushushu 60-62HRC

Umgca wemveliso uxhotyiswe ngoomatshini ababini be-TRUMPF be-laser welding kwi-double-machine linkage. Umpu we-welding oyintloko ujongene ne-welding yokungena ngokujulile ukuqinisekisa amandla, ngelixa intloko ye-welding ye-oscillating ibamba amajoyinti ekona. Ngaphaya koko, inkqubo yokuhlola okubonwayo kwi-intanethi ibona iziphene ze-weld ngexesha langempela, iqinisekisa ukuba amandla e-weld afikelela ubuncinane kwi-85% yezinto ezisisiseko.

Isilawuli sethu sokucheba singenisa sisuka e-italy

Ukusika indawo echanekileyo ephezulu

Ukunyamezela Ubude beprofayili egqityiweyo yi-1mm ngeepices nganye